Navigating the Environmental Impact of Manganese-Zinc Ferrite

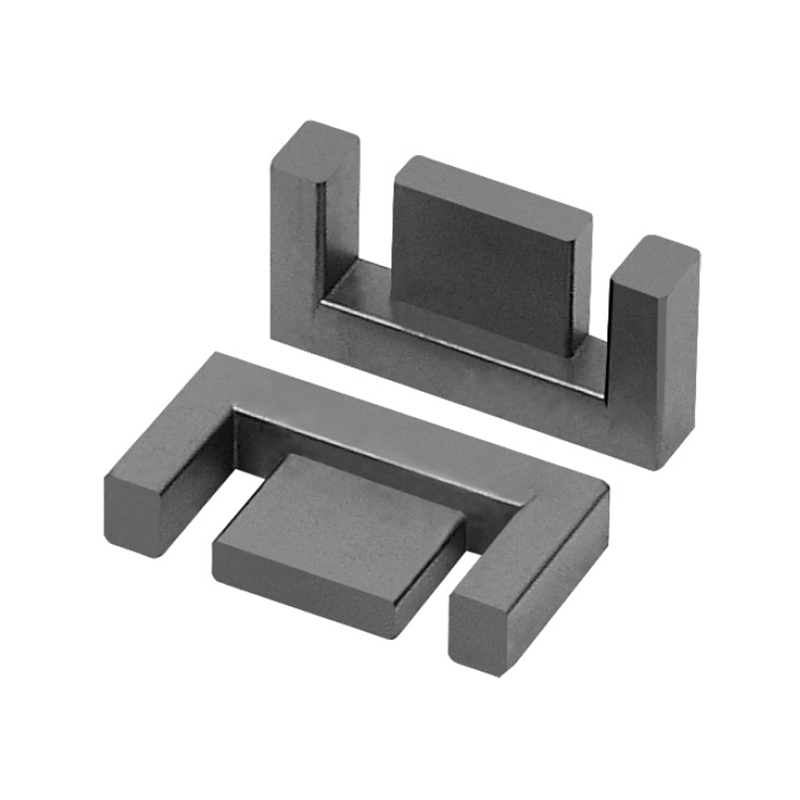

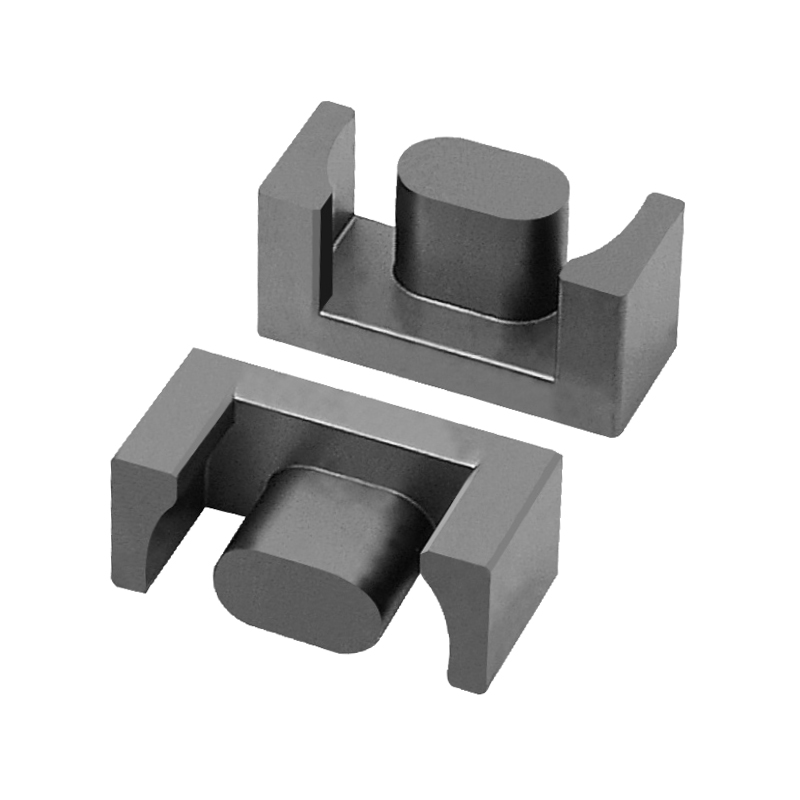

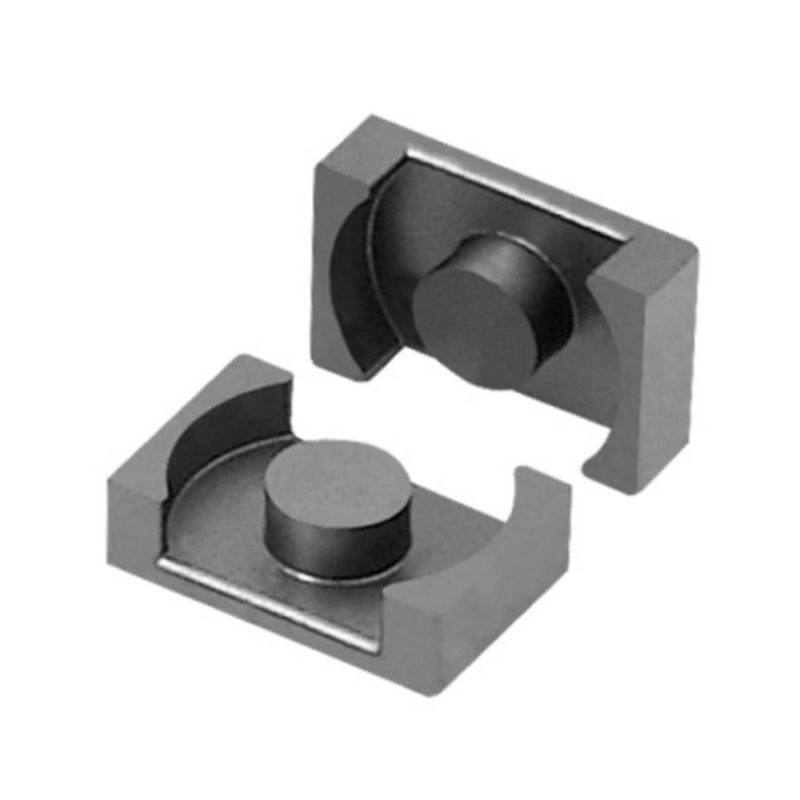

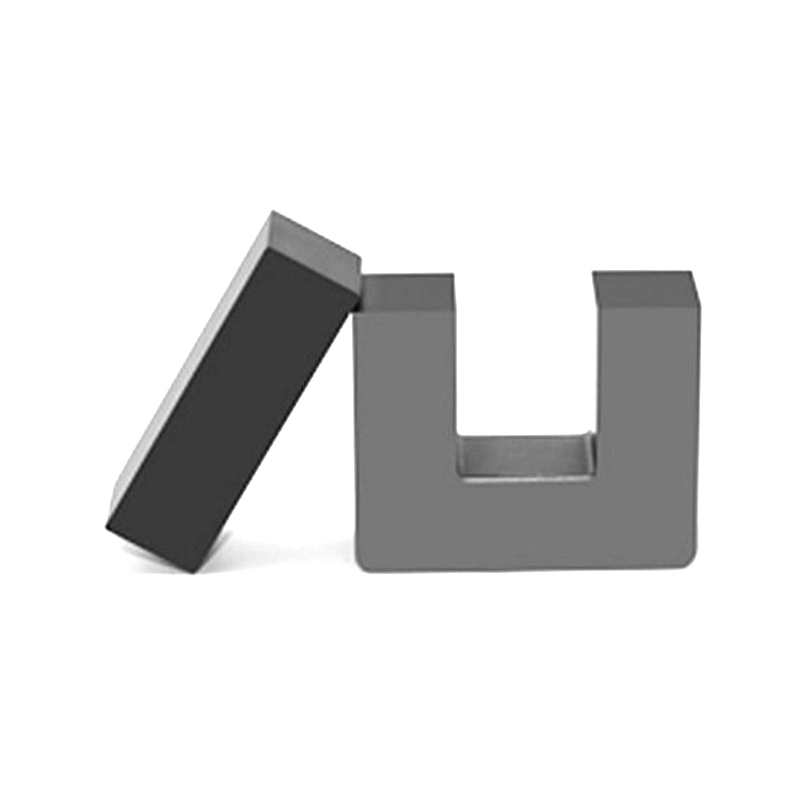

Manganese-zinc ferrite, a cornerstone material in the realm of soft magnetics, is celebrated for its exceptional magnetic properties, making it indispensable in various electronic devices. However, like many industrial materials, the production and disposal of manganese-zinc ferrite come with their own set of environmental considerations that cannot be overlooked. Understanding these implications is crucial as industries strive for sustainability while meeting technological demands.

The production process of manganese-zinc ferrite typically involves the ceramic method, which requires the careful handling of raw materials, including manganese oxide, zinc oxide, and iron oxide. While these materials are not classified as hazardous, the mining and processing stages can contribute to environmental degradation if not managed properly. Mining activities often lead to soil erosion, habitat destruction, and water contamination, raising concerns about the ecological balance in the regions where these minerals are extracted. Moreover, energy-intensive manufacturing processes result in greenhouse gas emissions, contributing to climate change. As the demand for manganese-zinc ferrite grows in various sectors, including electronics and renewable energy, manufacturers are increasingly pressured to adopt greener practices to mitigate these environmental impacts.

When it comes to the disposal of manganese-zinc ferrite, the challenges continue. As electronic waste (e-waste) becomes a growing global issue, the presence of ferrite materials in discarded devices raises questions about their long-term environmental effects. Although manganese-zinc ferrite is generally stable and non-toxic, improper disposal can lead to resource wastage and the potential for leaching of metals into the soil and groundwater. Recycling initiatives for electronic components are gaining traction, and it is essential to develop efficient systems for recovering valuable materials, including ferrites, from old devices. These recycling efforts not only help reduce landfill waste but also promote a circular economy, where materials are reused and repurposed rather than discarded.

Additionally, manufacturers are exploring ways to minimize the environmental footprint of manganese-zinc ferrite production through innovations in material science. This includes developing eco-friendly alternatives to conventional processing methods and finding ways to utilize waste materials or by-products in the production cycle. Some companies are even investigating bio-based materials that could serve as substitutes for conventional ferrites, although these alternatives are still in the research phase. The ultimate goal is to create a sustainable model that balances the high-performance needs of technology with responsible environmental stewardship.

While Manganese-zinc ferrite is essential for modern electronics, its production and disposal come with notable environmental considerations. From the impacts of mining to the challenges of e-waste, a holistic approach is needed to address these issues. As industries continue to innovate and adapt, the focus on sustainable practices and recycling will play a pivotal role in ensuring that manganese-zinc ferrite can contribute to technological advancements without compromising the health of our planet. Balancing performance with ecological responsibility is not just a challenge; it’s an opportunity to redefine how we interact with the materials that power our world.

中文简体

中文简体