Unraveling the Frequency Response of Manganese-Zinc Ferrite

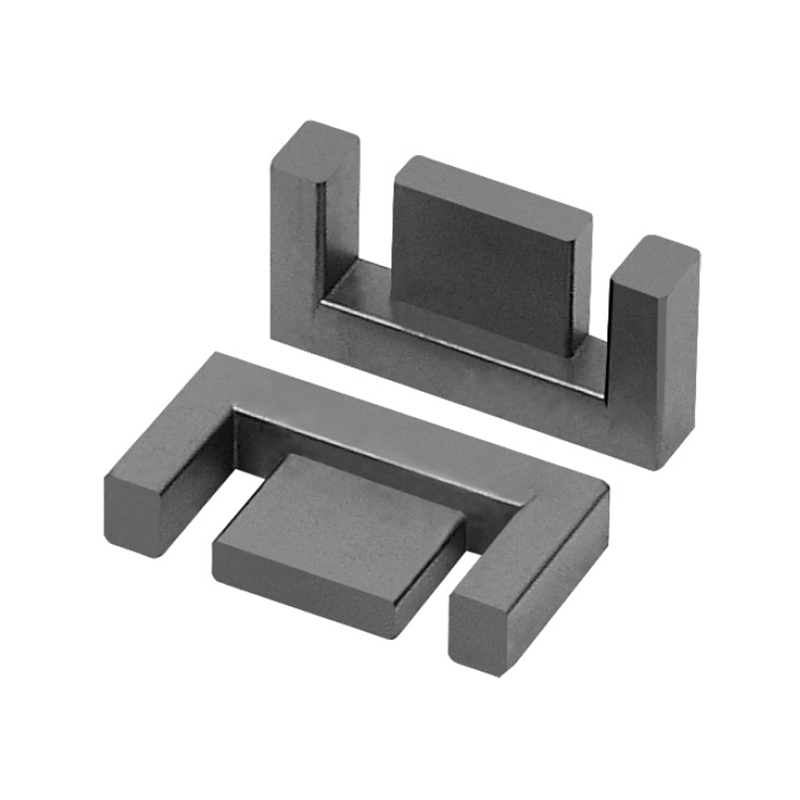

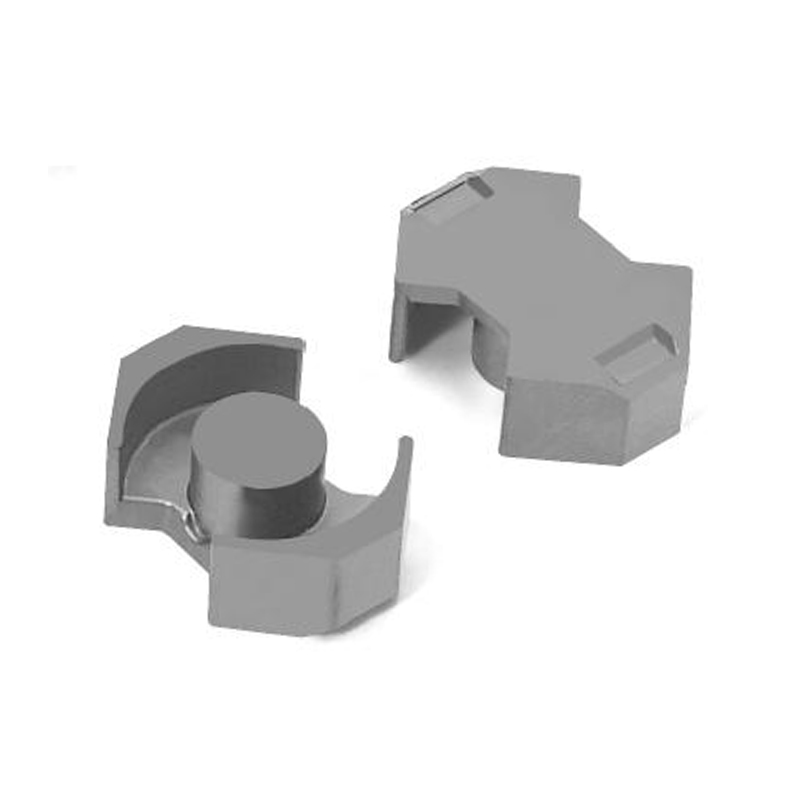

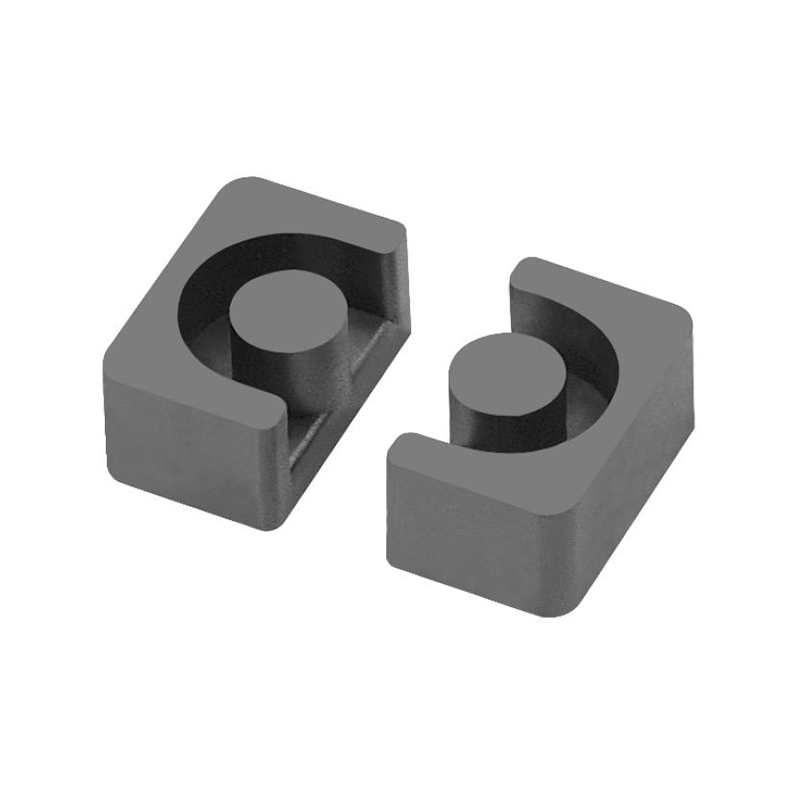

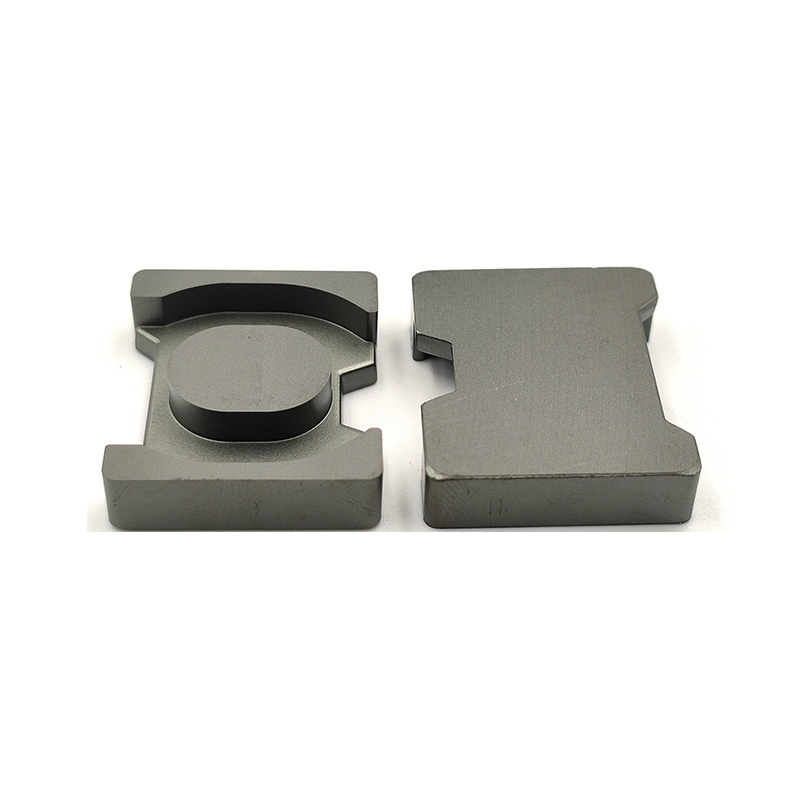

Manganese-zinc ferrite, a prominent soft magnetic material, plays a vital role in the world of electronics, especially in the construction of inductors and transformers. Its unique spinel crystal structure provides an exceptional combination of magnetic properties, particularly its high initial permeability and low core losses at lower frequencies. But what truly sets manganese-zinc ferrite apart is its frequency response, which significantly influences its performance across various applications.

The frequency response of manganese-zinc ferrite determines how effectively it can store and transfer magnetic energy in an alternating current environment. As the frequency of operation increases, the material's permeability and core losses exhibit distinct behaviors. At lower frequencies, such as those typically found in power electronics, manganese-zinc ferrite displays high permeability, allowing inductors and transformers to efficiently transfer energy with minimal losses. This characteristic makes it ideal for applications like power supplies, where smooth energy flow is crucial. However, as the frequency increases into the kilohertz and megahertz ranges, the material begins to experience eddy current losses and hysteresis losses that can degrade its performance. These losses arise from the magnetic domains within the ferrite material, which struggle to keep up with the rapid changes in magnetic field direction.

Understanding this frequency response is essential for engineers and designers when selecting the appropriate material for specific applications. For instance, in the case of inductors, where the goal is often to maximize inductance while minimizing resistance, manganese-zinc ferrite’s favorable low-frequency performance becomes a significant asset. However, for high-frequency transformers, such as those used in RF applications, alternative materials may be better suited due to their superior high-frequency characteristics. This balancing act is crucial; choosing the wrong ferrite material could lead to increased energy losses and reduced efficiency, ultimately affecting the device's overall performance.

Moreover, the composition of Manganese-zinc ferrite can be tailored to optimize its performance for particular frequency ranges. By adjusting the ratio of manganese to zinc, manufacturers can create ferrite materials that cater specifically to the requirements of a given application. This ability to customize properties means that engineers can devise solutions that maximize performance while keeping costs manageable. It’s an intricate dance of material science and engineering principles that highlights the versatility and practicality of manganese-zinc ferrite in modern electronics.

The frequency response of manganese-zinc ferrite is a critical factor that influences its application in inductors and transformers. Understanding how this material behaves across different frequency ranges allows engineers to harness its unique properties effectively, ensuring efficient energy transfer and minimal losses in a variety of electronic devices. As technology continues to evolve and demand for high-performance materials grows, the importance of manganese-zinc ferrite remains as relevant as ever, proving that in the realm of soft magnetic materials, frequency response is indeed a key player.

中文简体

中文简体