What are the applications and challenges of Soft Magnetic Ferrites in transformers and inductors?

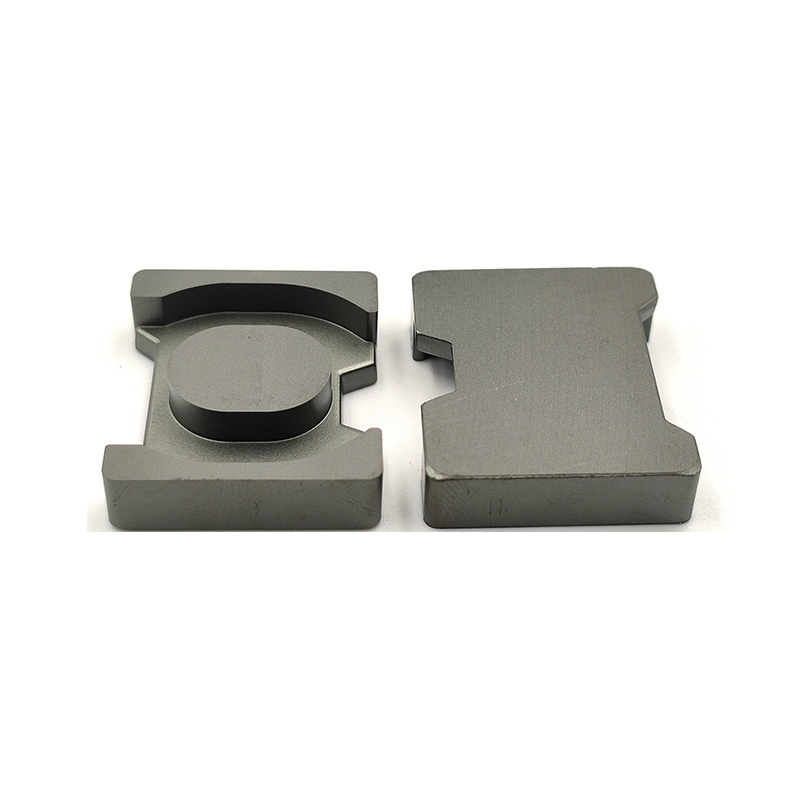

Soft Magnetic Ferrites are widely used in transformers and inductors, especially in high-frequency electronic devices and switching power supplies, due to their excellent magnetic properties, low losses and high magnetic permeability. However, despite its many advantages in these fields, it also faces some technical challenges.

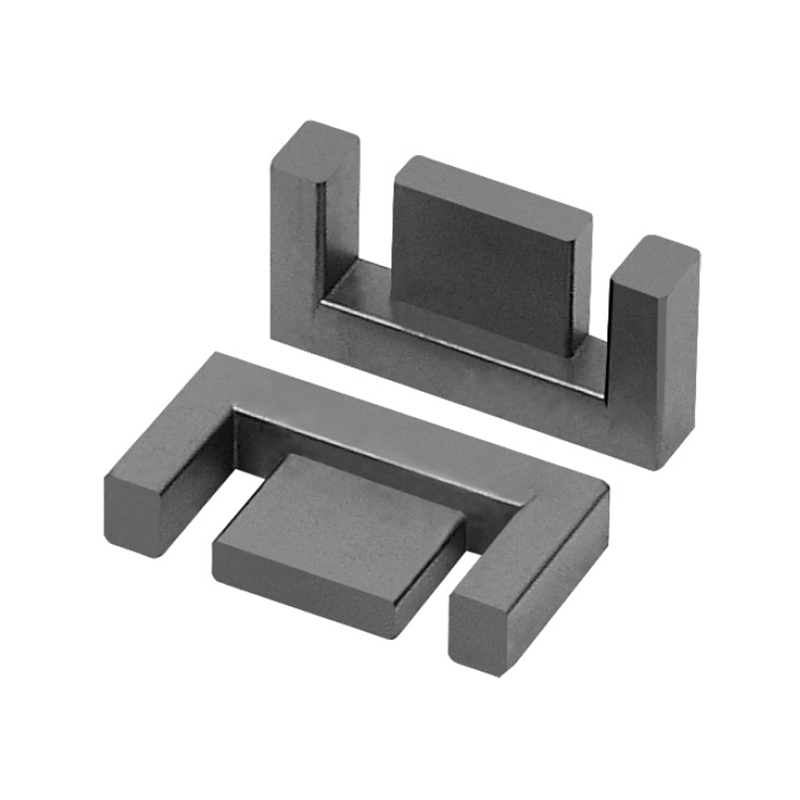

High-frequency transformers Soft ferrites are one of the most commonly used materials in high-frequency transformers, especially in devices such as switching power supplies and DC-DC converters, where the operating frequency is usually tens to hundreds of kilohertz or even higher. Soft ferrites can maintain low losses and high magnetic permeability at high frequencies, which is the main reason why they are favored in these applications.

Soft ferrites can effectively operate at high frequencies, reduce core losses, and improve power conversion efficiency. Therefore, they are widely used in modern power supply designs, such as laptops, mobile phone chargers, etc.

In these devices, soft ferrite transformers help electronic devices achieve miniaturization and high efficiency by increasing power density and reducing conversion losses.

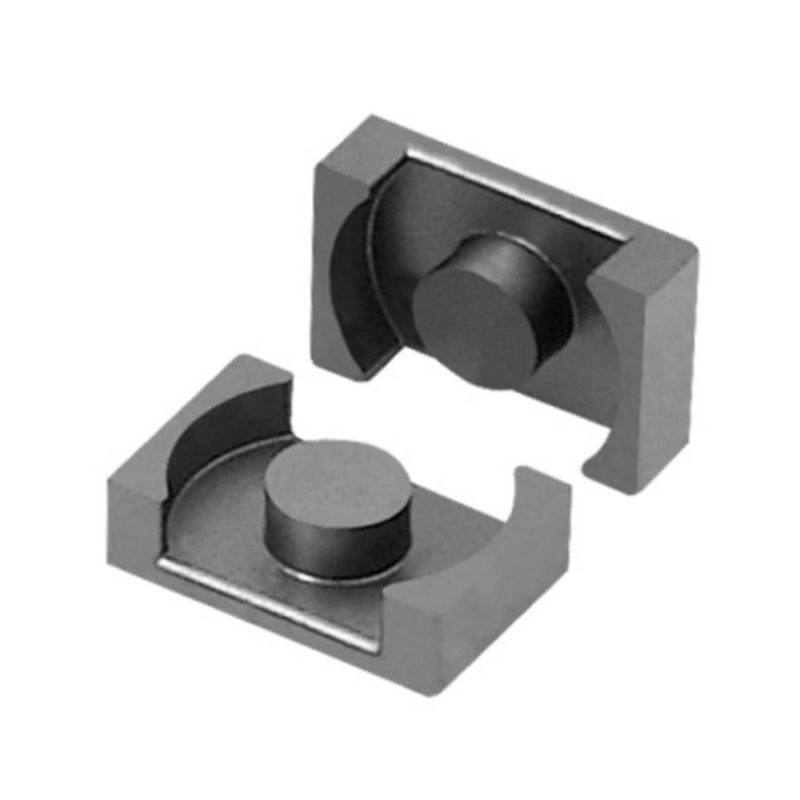

Soft ferrite inductors are widely used in high-frequency signal processing, filtering circuits, and energy storage components. Its high magnetic permeability can enhance the inductance value of the coil and provide higher inductance in the same volume. In addition, the low loss characteristics of ferrite are particularly important in high-frequency applications.

In switching power supplies and radio frequency applications, energy storage inductors use soft ferrites as magnetic cores to reduce energy loss and improve the efficiency of storing and releasing electrical energy.

Ferrite inductors are used in electromagnetic interference (EMI) filters to eliminate high-frequency noise signals to ensure the normal operation of circuits. They are commonly found in power systems, household appliances, and communication equipment.

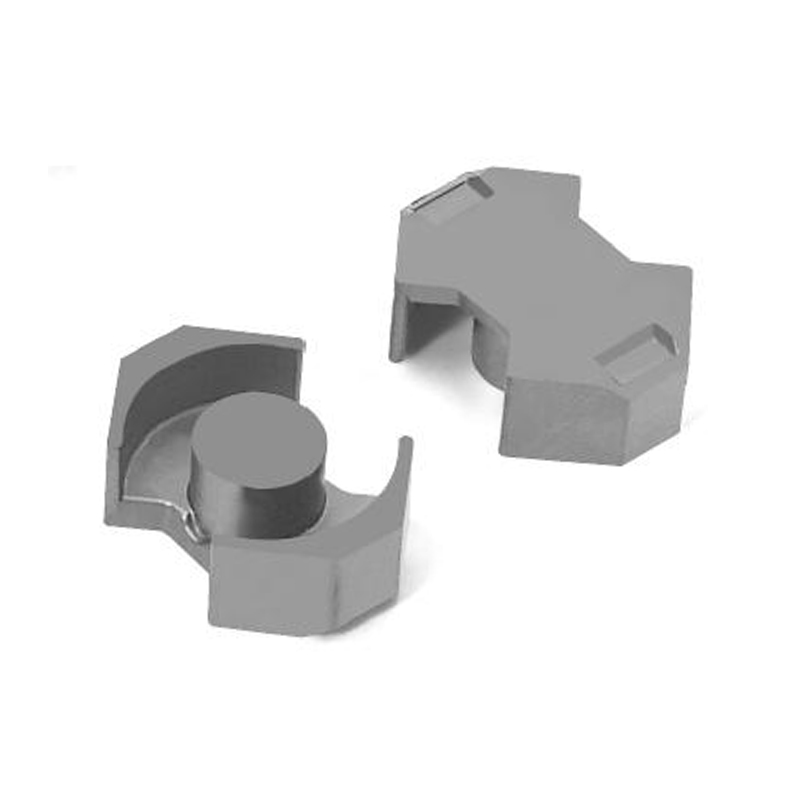

High-frequency loss Although soft ferrites are suitable for high-frequency applications, hysteresis losses and eddy current losses still increase significantly as the frequency increases further. This becomes particularly prominent in applications where the operating frequency exceeds 1MHz, resulting in a decrease in efficiency. Therefore, in an extremely high-frequency working environment, selecting ferrite materials with low loss characteristics or using new processing technologies has become an important challenge for designers.

The magnetic properties of Soft Magnetic Ferrites are sensitive to temperature. In particular, at high temperatures, the magnetic permeability and saturation flux density decrease, affecting the overall efficiency of transformers and inductors. Especially in switching power supplies and high-power electronic devices, temperature changes can lead to unstable device performance. Therefore, designing ferrite materials with good performance over a wide temperature range is a problem that needs to be solved urgently.

The Curie temperature is the critical point at which soft ferrite materials lose their magnetism, usually between 100°C and 300°C. As the temperature increases, the decrease in magnetism directly affects the efficiency of transformers and inductors. In high-temperature applications (such as industrial power supplies or high-frequency transformers), ferrite materials with lower Curie temperatures may not meet the requirements, so it is necessary to develop materials with higher Curie temperatures to adapt to more stringent working environments.

Soft ferrites are widely and important in transformers and inductors, especially in high-frequency, high-efficiency electronic devices. Its low loss, high magnetic permeability and adaptability to high-frequency operation make it a key material in electronic components. However, with the advancement of technology, the challenges faced by soft ferrites in high-frequency loss, temperature stability, material strength and cost control are also intensifying. By improving material formulations and manufacturing processes, the development of new soft magnetic materials will be an important direction to further enhance their application effects in the future.

中文简体

中文简体