How do the grain structure and microstructure of Mn-Zn ferrite cores influence their magnetic properties?

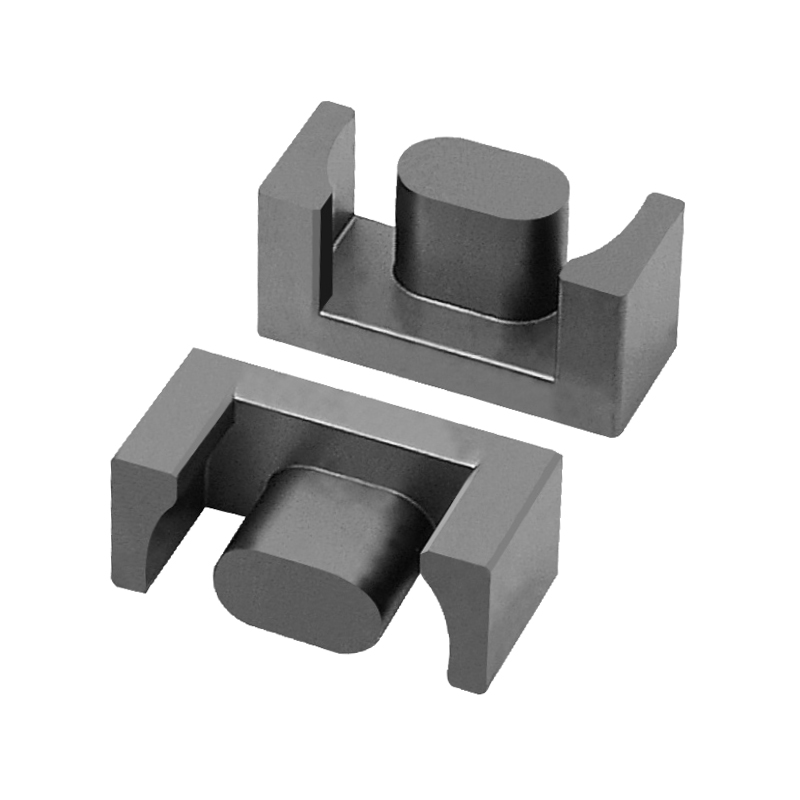

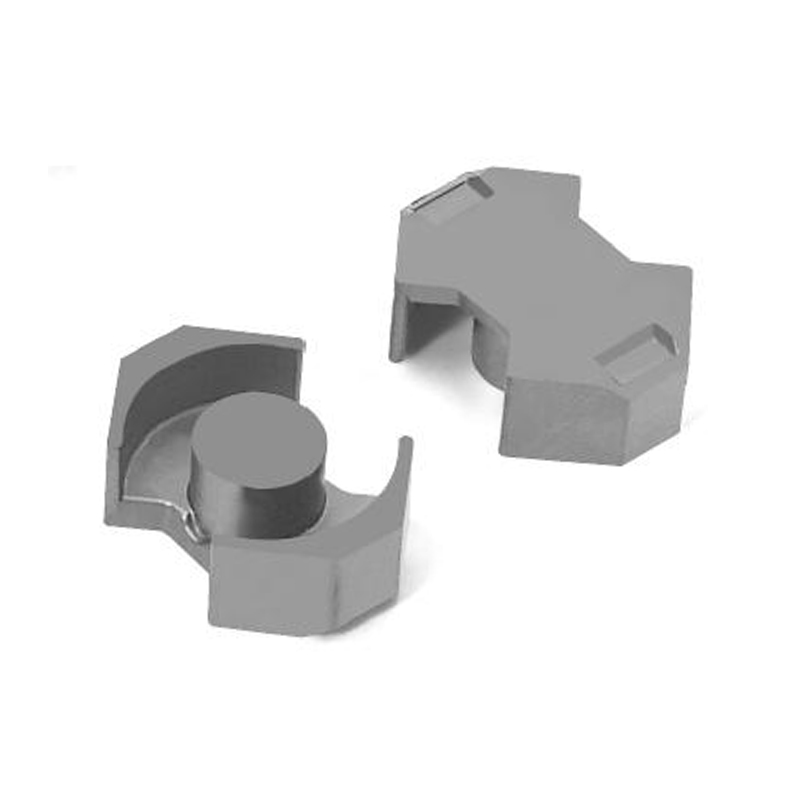

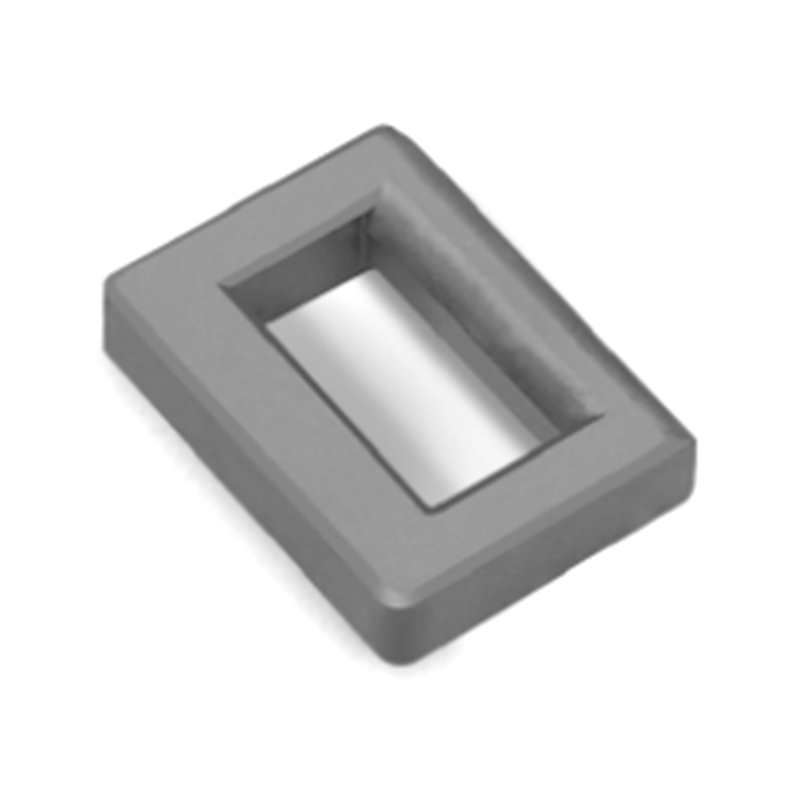

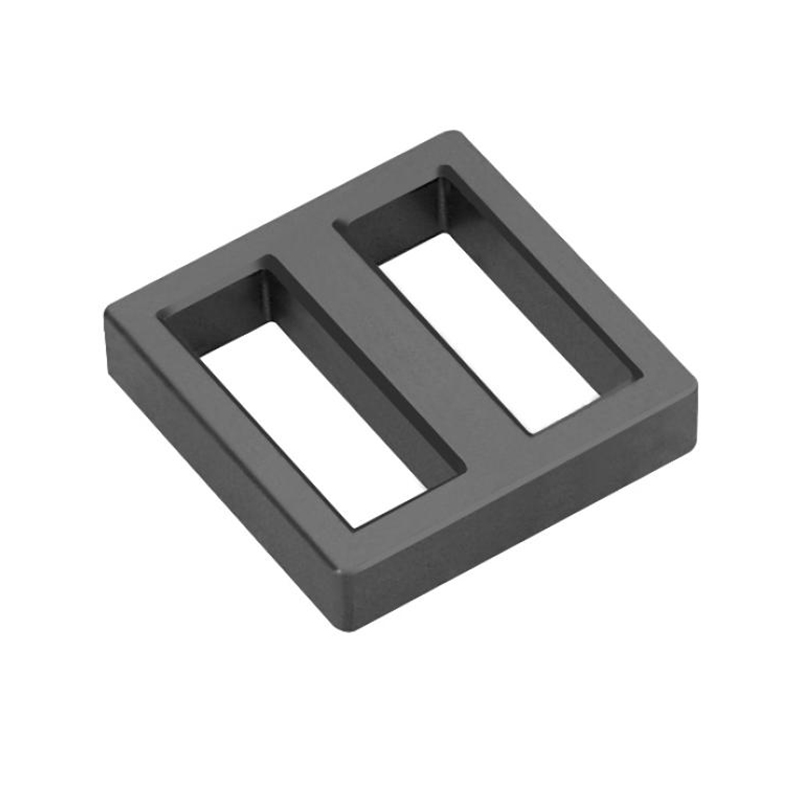

In the world of electronics, ferrite cores are indispensable components for inductors and transformers, especially in high-frequency applications. Among various types of ferrites, manganese-zinc (Mn-Zn) ferrite cores are widely used due to their excellent magnetic properties. However, the performance of these cores is heavily influenced by their grain structure and microstructure.

Grain Structure: The Building Blocks of Magnetism

The grain structure of Mn-Zn ferrite cores refers to the arrangement, size, and shape of the crystallite grains within the material. Typically, a finer grain size is associated with enhanced magnetic properties. This is because smaller grains can reduce the magnetic domain size, allowing for easier magnetization and demagnetization. As a result, Mn-Zn ferrites with a fine-grained structure exhibit lower coercivity and higher permeability, which are critical for efficient energy transfer in inductive devices.

Research has shown that optimizing the sintering temperature and time during the manufacturing process can significantly influence the grain size. For example, a study published in the Journal of Magnetism and Magnetic Materials found that sintering Mn-Zn ferrite at elevated temperatures leads to larger grain sizes, which in turn increases losses during high-frequency operation. Thus, controlling the grain structure is vital for tailoring the magnetic properties to meet specific application needs.

Microstructure: The Hidden Details

Beyond grain size, the microstructure of Mn-Zn ferrites encompasses the distribution of porosity, secondary phases, and impurities within the material. These factors play a crucial role in determining the core's magnetic performance. For instance, the presence of porosity can disrupt the uniformity of the magnetic field, leading to increased losses and decreased efficiency. Therefore, minimizing porosity through careful processing techniques is essential for achieving optimal magnetic performance.

Furthermore, secondary phases, such as unwanted crystalline structures that form during synthesis, can act as barriers to domain wall motion, adversely affecting the magnetic properties. A well-documented phenomenon is that the presence of these secondary phases can lead to increased coercivity and reduced permeability, both of which are undesirable for ferrite core applications. Studies have shown that maintaining a pure phase in the microstructure can enhance the magnetic response, making it critical to control the synthesis environment.

The Interplay Between Grain Structure and Microstructure

The relationship between grain structure and microstructure is intricate and significantly impacts the magnetic properties of Mn-Zn ferrites. For instance, a refined grain structure can improve magnetic performance, but if the microstructure is compromised with excessive porosity or secondary phases, the benefits may be negated. Therefore, a holistic approach to material design is essential.

Advanced characterization techniques, such as scanning electron microscopy (SEM) and X-ray diffraction (XRD), can help researchers gain insights into the grain and microstructural features of Mn-Zn ferrites. This understanding enables the development of optimized processing routes to achieve the desired balance between grain structure and microstructure, ultimately leading to superior magnetic performance.

The grain structure and microstructure of Mn-Zn ferrite cores are pivotal to their magnetic properties. Fine grain size and a well-controlled microstructure contribute to improved magnetic performance, making these materials ideal for high-frequency applications. As technology continues to advance, further research and optimization of these microstructural features will pave the way for even more efficient and effective ferrite cores. By appreciating the nuances of grain structure and microstructure, we can harness the full potential of Mn-Zn ferrites in the ever-evolving landscape of electronic devices.

中文简体

中文简体